The company ARSIN Systems AG

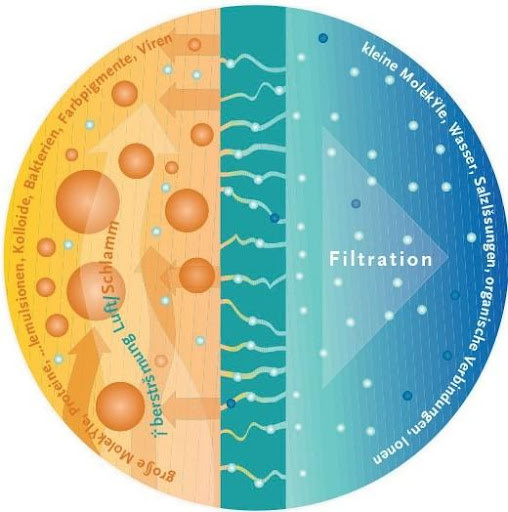

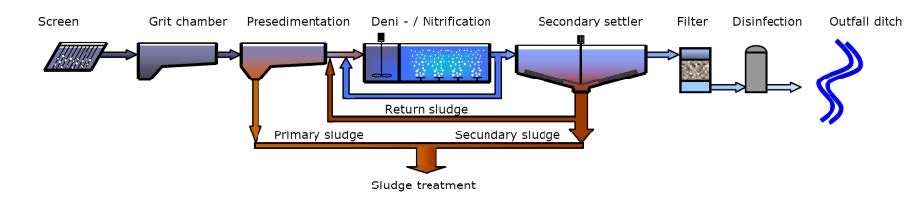

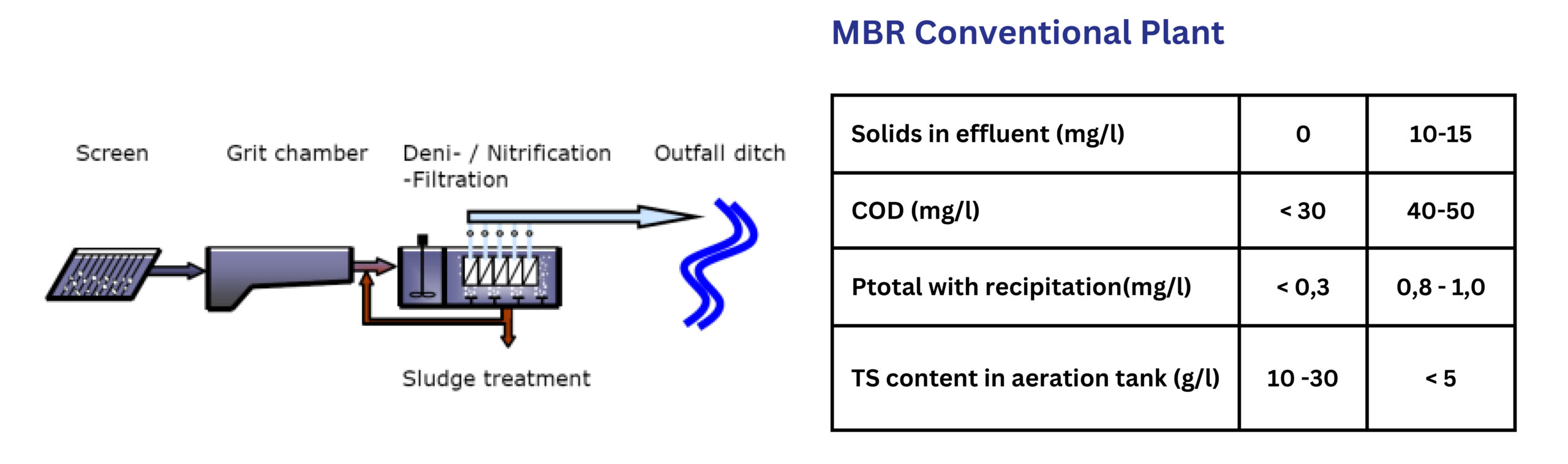

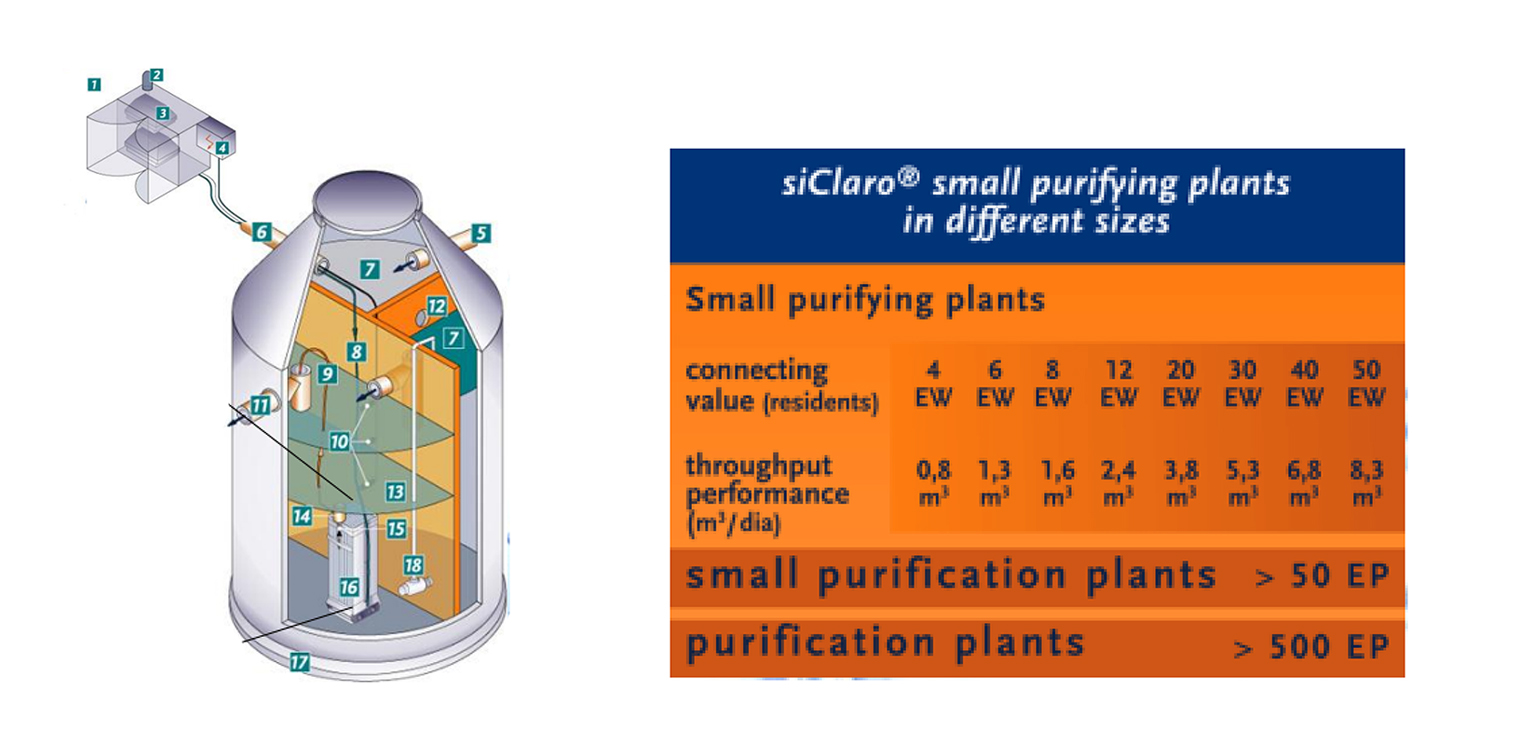

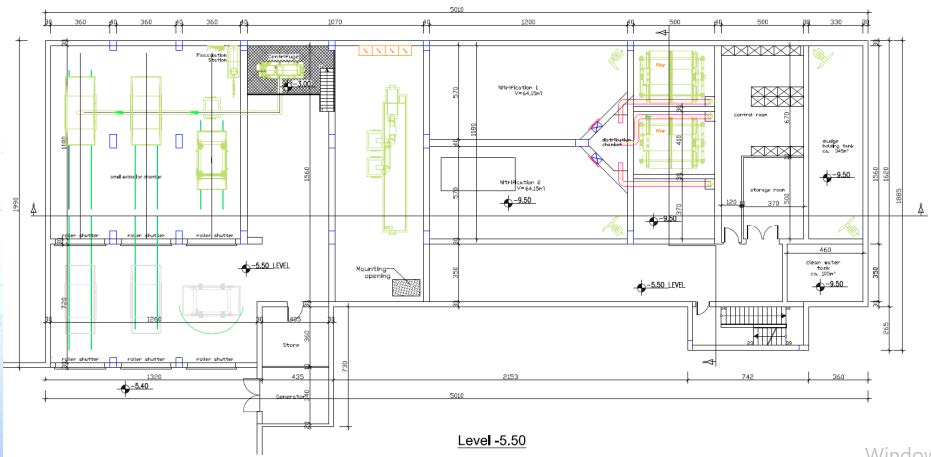

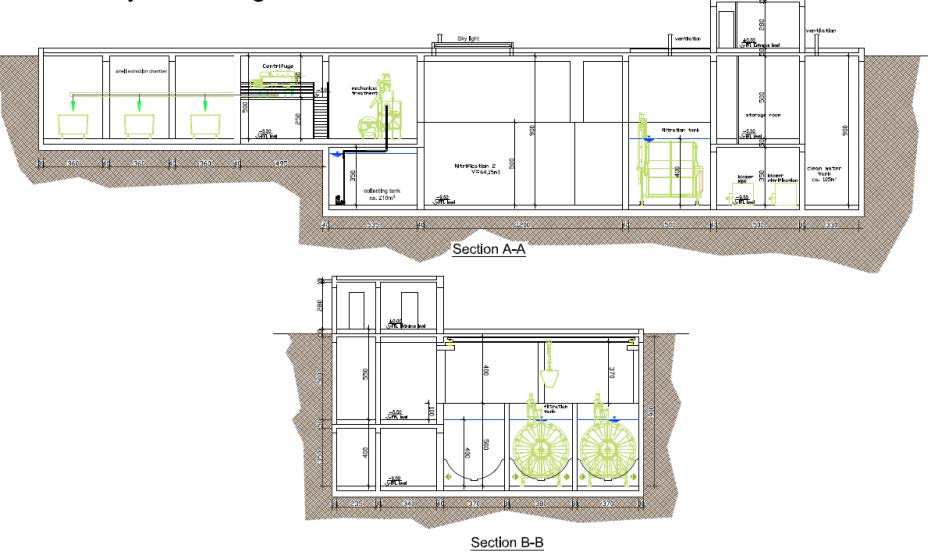

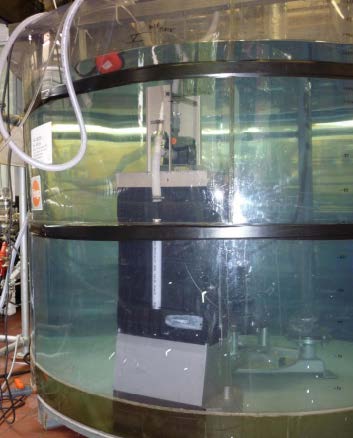

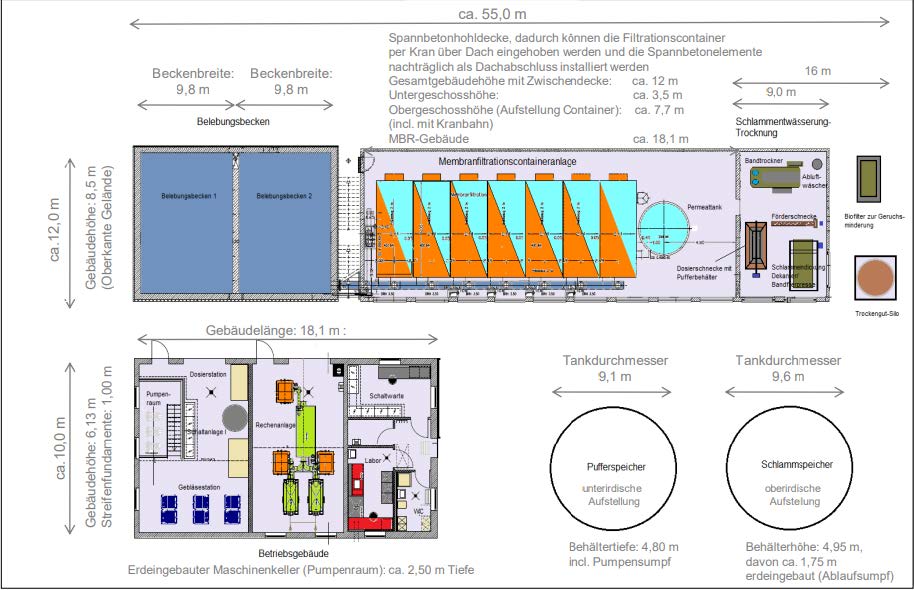

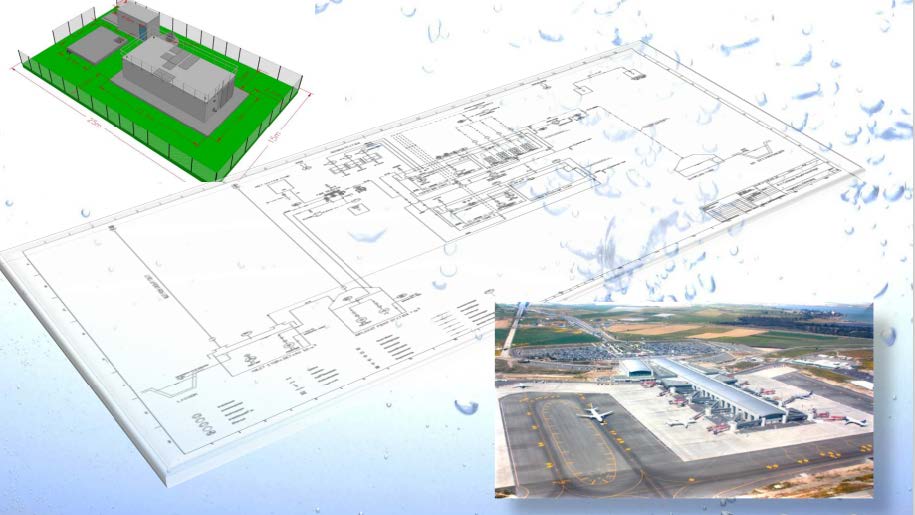

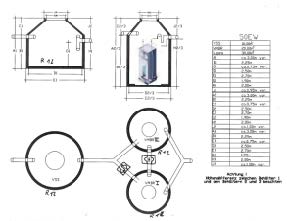

Water is the necessary basis for all life. ArsinSystems guarantees the highest level ofwastewater treatment with the membranefilters in the siClaro series and the biologicalsewage treatment plants in the BMA series.

Arsin Systems ensures that water is free frompathogenic microorganisms, contains noenvironmentally-harmful pollutants and iscleaned of turbid matter that could affectquality. This way, the water can be re-used tosave natural resources.