WHAT IS PLASMA ?

Basically, plasma is the thermal energy only at the highest temperature. Plasma in nature, is produced after the air around the lightning is converted into approximately 20.000 °C when the thunderbolt heats up the air enormously. As the Plasma is sometimes called as the fourth form of element other than the forms of gas, liquid or solid.

Our aim is, not only take place of the most common methodology of burning the solid waste, but by using the effective and environmentally friendly methods, to reach highest efficiency and highest valuable products. Plasma gasification technology is the most effective and environmentally friendly method for solid waste treatment and energy utilization.

Working Principle of Plasma Technology:

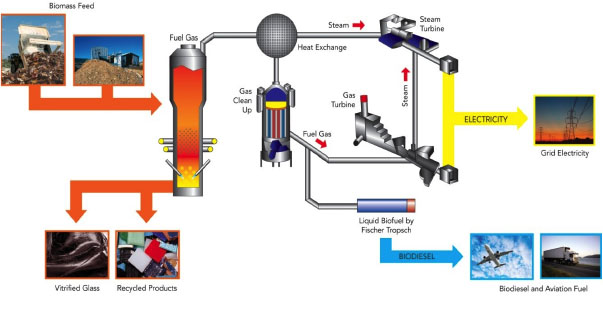

It is applied by giving electricity to torches and an arc is created between the torch electrots. Gas, which does not transmit the electricity, is passed through these two electrots and hence a Plasma, which has an internal temperature of 10.000 ° C -14.000° C, is obtained. In this case, the temperature in the edge of the torch is around 2.500 ° C -5.000 ° C. The waste disposal is directly transferred to the top of the heat converter and collected in the container of the reactor. The transferred plasma torches directed to the container in the high temperatures cannot burn the organic materials as there is no oxygen at such high temperature. Hence, a gas is produced in which carbonmonoxide (CO), Hydrogen (H₂) and Nitrogen (N) exists. This gas is processed and directed to synthetic turbine or gas motors to produce electrical energy.

Economical Assessment of Plasma Plant:

A Plasma Plant is relatively more economic from the investment cost perspective compared to conventional burning plants having similar capacity and size.The operation costs are also relatively low compared to sdandard burning plants. Considering the high level elimination costs for clinical and dangerous wastes, the investment costs for a Plasma Plant can be amortized in a very short time.